Cheesemaking at home is no longer a lost art but is experiencing a revival. People are learning the joy that comes from cheesemaking and enjoying the fruit of their labor. You can too but first you need to know a few basics that I will share.

Interested in cheesemaking at home? You will find this introduction to cheesmaking plus, 32 cheesemaking recipes in my Simple Cheesemaking ebook. Follow the link to find more wonderful cheese recipes with easy to follow instructions and much more!

Have you ever wanted to make your own Mozzarella, Feta, Ricotta, or some other cheese? Are you interested in learning cheesemaking at home? Equipped with the basics of cheese making, you can! And, be successful.

Cheese making basics are important to review for anyone interested in cheesemaking at home. Especially since cheese making is a lost art which is experiencing a revival. As people are moving toward becoming more self-sufficient they are becoming interested in cheesemaking at home once again.

The homesteading movement is also a contributor to the revival of cheesemaking at home as more people have their own family milk cow.

You might wonder what sparked my interest in cheese making and cheese making basics?

Well, in one word...

Vineyard.

When we moved from Alabama to west Texas to grow grapes, we left a cushy corporate job using our retirement, savings and investments to get started and for living expenses. With grapes, you normally must wait until the third year to have any harvest to speak of. So, we began to look for ways to save money.

One way we cut monthly expenses was having a family milk cow. Since she (Buttercup at that time and now Emme) produces anywhere from 2 to 8 gallons of milk daily, there is ample milk to supply our family's dairy products. We have all learned to make not only butter, yogurt, and kefir, but also cheese. All types: Mozzarella, Feta, Ricotta, Cottage Cheese, Cheddar, Swiss....

I thought it might be interesting for those of you who have never thought of cheesemaking at home to know a bit about the basics. The process is actually very simple and producing cheese in your own kitchen is rewarding. I hope this overview of the basics and future recipes will encourage you to give it a try.

Cheesemaking at Home

1. Basic Ingredients Needed for Cheesemaking at Home

Milk

Even if you do not have your own cow or access to fresh raw milk, you can still make fresh cheese at home. Store bought whole or skim milk may also be used. Experiment with different brands of homogenized milk to see which works the best. Calcium chloride may be added to homogenized milk to encourage coagulation. One word of caution: Do not use ultra-pasturized milk. The high heat of this process destroys the enzymes in the milk which are necessary to cheese making.

Rennet

Rennet is an enzyme in either animal or vegetable form which causes the milk to coagulate. The animal form comes from the fourth stomach of an unweaned calf. Both are available in either tablet or liquid form and should be dissolved in cool water before adding it to the milk. In recipes, ¼ tablet usually equals ½ teaspoon liquid rennet. While animal rennet is more expensive, it works better in cheeses that age over longer periods of time without giving a bitter flavor. I purchase animal rennet through my affiliate, Here.

Do NOT use junket rennet.

Calcium Chloride

Used to achieve a firmer setting curd when store-bought milk is used. It is available from my affiliate as a liquid calcium chloride.

Lipase Powder

Italian lipase powder add the mild flavor to Italian cheeses like mozzarella, feta, parmesan and others. Available from my affiliate, Italian Lipase Powder

Salt

I use sea salt (from my affiliate -where to buy REAL salt)

Cheese salt can also be used since it melts easily and does not contain iodine. Available from my affiliate: Cheese Salt

Citric Acid

Citric acid powder is used to increase the acid level in the milk. I use it when making mozzarella cheese. For the citric acid I use (from my affiliate), Click Here

Starter Culture - There are 2 basic types:

Mesophilic - A bacterial culture that lives and multiplies in warm temperatures NOT hot ones. Milk heated above 107F kills the mesophilic culture. Used in Cheddar, Muenster, and Monterrey Jack cheeses. Available from my affiliate: Click Here

Thermophilic - A bacterial culture that lives and multiplies in hot temperatures. Used in Parmesan and Swiss cheeses. Available from my affiliate: Click Here

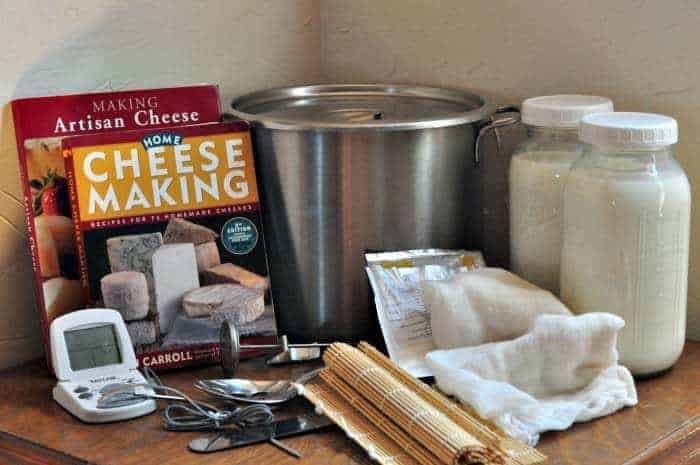

2. Cheese Making - Basic Equipment

Stock Pot - A heavy gauge stainless steel pot works best as it distributes the heat more evenly. Depending on the size of the batch, I use either a 3, 5, or 10 gallon pot.

Thermometer- I always used the stainless steel with an easy to read dial from my affiliate, Here. Until recently, that is, and now I use this (from my affiliate) digital thermometer. The digital thermometer is great because it also has an alarm which can be set to sound when the desired temperature is reached.

Cheesecloth - Used to drain the whey from the curd.

Cheese Mat - Used to dry hard cheeses after pressing. I now use a bamboo type but have used a wicker paper plate holder.

Wax - Used to prevent hard cheeses from drying out while aging.

Long Bladed Knife - Used to cut the curd.

Stainless Steel Spoon - Used for stirring.

Measuring Spoons and Cups

3. Cheese Making - Basic Process

The protein in the milk solidifies to form a curd. The curd separates from the water or "whey" in the milk. Milk sugar and some proteins, as well as minerals are in the whey. Coagulation is caused by lactic acids in soft cheeses and an enzyme in rennet in hard cheeses.

After about an hour of sitting, the coagulated milk, or curd, must be cut into smaller sizes in order for the whey to separate. Cutting increases the surface area allowing the whey to drain more quickly.

In soft cheeses, the curd is usually drained through a cheesecloth. In hard cheeses the curd is heated to firm it, then pressed to form a solid cheese. Using different cultures and different temperatures for varying amounts of time, both help produce the flavors of various cheeses.

Important Point:

Cleanliness is of utmost importance. In cheese making, you are trying to provide the optimum growing conditions for particular bacteria. Take care to prevent the growth of wrong bacteria. Wash your hands before performing any steps in the cheese making process. Sterilize your equipment before beginning.

I keep a gallon jug of dilute bleach (¼ c bleach per 1 gal water) to rinse all my cheese making equipment. Before beginning, I rinse the pot, lid, thermometer, stirring spoon, knife (before cutting the curd) anything which will come into contact with the milk. Once rinsed with the bleach solution, I then rinse with water. Bleach residue left behind will kill the enzymes necessary for coagulation. So, even though my bleach solution is dilute, I rinse it with water just to be safe.

4. Cheesemaking at Home - Resources

If I could only have one cheese making book, besides my own Simple Cheesemaking, it would be the one I purchased from my affiliate partner, Home Cheese Making: Recipes for 75 Delicious Cheeses by Ricki Carroll.

Another very good book, also available from my affiliate, is Making Artisan Cheese by Tim Smith which gives other recipes and techniques.

In addition to the links provided above, I also order supplies from New England Cheese Making Supply - be sure to check out their website for many recipes and helpful hints.

Cheryl Wedding says

Could you tell me if either of the books that you mention have metric measurements for cheese making.

Thanks from Australia

Dina-Marie says

Cheryl, I just checked my copies and Making Artisan Cheese does!